EIGHTEEN SOUND ND1060

҆ifra: 4884

139,36 EUR

*Cijena sa popustom moŇĺe se ostvariti ukoliko se plańáa gotovinom, virmanom (preko rańćuna) ili debitnom i kreditnom karticom odmah i odjednom.

Prikazana cijena je za komad.

Garantiramo najniŇĺu cijenu na trŇĺiŇ°tu!

U sluńćaju da pronańĎete isti proizvod po povoljnijoj cijeni,

molimo Vas da nas kontaktirate na:

info@player.hr

HF Neodymium Driver 8 Ohm

·         108 dB SPL 1W / 1m average sensitivity

·         1 inch exit throat

·         44 mm (1 3/4 inch) edgewound

·         aluminum voice coil

·         80 Watt program power handling

·         Treated polyethylene diaphragm

·         Proprietary phase plug design

·         Neodymium magnetic structure

·         Excellent thermal exchange

The ND1060 1 inch exit neodymium high frequency compression driver has been designed for use in high quality audio system designs.One advancement in the ND1060 is its new innovative diaphragm assembly made from a proprietary treated Polyethylene material. Consequently, the ND1060, with its inherent superior diaphragm dimensional stability (160¬įC), is able to maintain constant behavior during its whole working life. Moreover, the proprietary treated polyethylene film, with its very high value of modulus of elasticity (50% more than standard Mylar and 100% more than polyimide film), is capable of superior transient and intermodulation distortion response. The flat suspension shape has been designed to maintain low stiffness and low mid band distortion and response. An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Nomex shows a 30% higher value of tensile elongation at a working operative temperature (200¬įC) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Further, this proprietary former material is also suitable for use in high moisture content environments. Equipped with unique proprietary phase plug architecture, the ND1060 has been designed to give high level manufacturing consistency and a smooth coherent wavefront at the horn entrance across the whole working frequency range. With its short openings and high flare rate value, this phase plug design assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction. By careful use of elementary pieces of neodymium magnets, Eighteen Sound engineers have developed a powerful neodymium magnet assembly capable of reaching 18KGauss in the gap, within a compact and lightweight structure. A copper ring on the pole piece reduces inductance above 10 kHz, improving phase and impedance linearization. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading. Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover which facilitates a lower power compression value. The ability to perform properly under inclement weather conditions is a key-point in the Eighteen Sound philosophy. A special treatment has been applied to the magnet and the top and back plates of the magnetic structure making the ND1060 driver more resistant to the corrosive effects of salts and oxidization. This treatment is more effective than any other treatment used by other manufacturers.

GENERAL SPECIFICATIONS

Throat Diameter

25,4 mm (1 in)

Rated Impedance

8 ohm

DC Resistance

5,3 Ohm

Minimum Impedance

7 Ohm at 4000Hz

Le (at 1kHz)

67 ¬ĶH

AES power

40 W above 1,6 kHz

Program power

80 W above 1,6 kHz

Sensitivity(1W@1m)

108 dB

Frequency Range

1600Hz √∑ 20kHz

Recomm. Xover Frequency

1600Hz (12dB/oct slope)

Diaphragm Material

Treated polyethylene

Voice Coil Diameter

44,4mm (1 3/4 in)

Voice Coil Winding Material

Edge-wound aluminum

Magnet Material

Neodymium

Flux Density

1,8 T

BL Factor

8,7 N/A

Polarity

Positive voltage on + terminal gives positive pressure in the throat

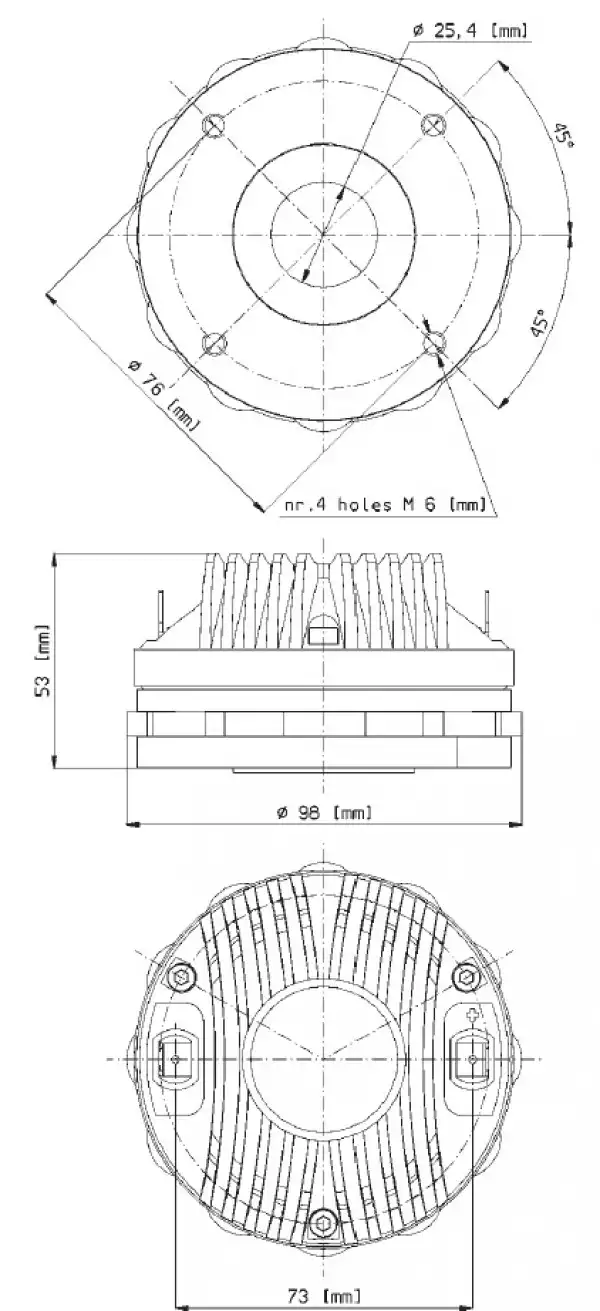

MOUNTING INFORMATIONS

Overall diameter

98 mm (3,9 in)

Mounting holes diameter

4 M6 holes 90¬į at √ė 76 mm (3 in)

Bolt circle diameter

76 mm (3 in)

Total depth

53 mm (2,1 in)

Net weight

1,1 Kg (2,4 lb)

Shipping weight

1,2 Kg (2,6 lb)

CardBoard Packaging dimensions

97x97x58 mm (3,8x3,8x2,3 in)

ND1060 MEASURED WITH 1W INPUT ON RATED IMPEDANCE AT 1M DISTANCE ON XT1086 HORN MOUTH AXIS

FREE AIR IMPEDANCE MAGNITUDE CURVE

·         108 dB SPL 1W / 1m average sensitivity

·         1 inch exit throat

·         44 mm (1 3/4 inch) edgewound

·         aluminum voice coil

·         80 Watt program power handling

·         Treated polyethylene diaphragm

·         Proprietary phase plug design

·         Neodymium magnetic structure

·         Excellent thermal exchange

The ND1060 1 inch exit neodymium high frequency compression driver has been designed for use in high quality audio system designs.One advancement in the ND1060 is its new innovative diaphragm assembly made from a proprietary treated Polyethylene material. Consequently, the ND1060, with its inherent superior diaphragm dimensional stability (160¬įC), is able to maintain constant behavior during its whole working life. Moreover, the proprietary treated polyethylene film, with its very high value of modulus of elasticity (50% more than standard Mylar and 100% more than polyimide film), is capable of superior transient and intermodulation distortion response. The flat suspension shape has been designed to maintain low stiffness and low mid band distortion and response. An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Nomex shows a 30% higher value of tensile elongation at a working operative temperature (200¬įC) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Further, this proprietary former material is also suitable for use in high moisture content environments. Equipped with unique proprietary phase plug architecture, the ND1060 has been designed to give high level manufacturing consistency and a smooth coherent wavefront at the horn entrance across the whole working frequency range. With its short openings and high flare rate value, this phase plug design assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction. By careful use of elementary pieces of neodymium magnets, Eighteen Sound engineers have developed a powerful neodymium magnet assembly capable of reaching 18KGauss in the gap, within a compact and lightweight structure. A copper ring on the pole piece reduces inductance above 10 kHz, improving phase and impedance linearization. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading. Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover which facilitates a lower power compression value. The ability to perform properly under inclement weather conditions is a key-point in the Eighteen Sound philosophy. A special treatment has been applied to the magnet and the top and back plates of the magnetic structure making the ND1060 driver more resistant to the corrosive effects of salts and oxidization. This treatment is more effective than any other treatment used by other manufacturers.

GENERAL SPECIFICATIONS

Throat Diameter

25,4 mm (1 in)

Rated Impedance

8 ohm

DC Resistance

5,3 Ohm

Minimum Impedance

7 Ohm at 4000Hz

Le (at 1kHz)

67 ¬ĶH

AES power

40 W above 1,6 kHz

Program power

80 W above 1,6 kHz

Sensitivity(1W@1m)

108 dB

Frequency Range

1600Hz √∑ 20kHz

Recomm. Xover Frequency

1600Hz (12dB/oct slope)

Diaphragm Material

Treated polyethylene

Voice Coil Diameter

44,4mm (1 3/4 in)

Voice Coil Winding Material

Edge-wound aluminum

Magnet Material

Neodymium

Flux Density

1,8 T

BL Factor

8,7 N/A

Polarity

Positive voltage on + terminal gives positive pressure in the throat

MOUNTING INFORMATIONS

Overall diameter

98 mm (3,9 in)

Mounting holes diameter

4 M6 holes 90¬į at √ė 76 mm (3 in)

Bolt circle diameter

76 mm (3 in)

Total depth

53 mm (2,1 in)

Net weight

1,1 Kg (2,4 lb)

Shipping weight

1,2 Kg (2,6 lb)

CardBoard Packaging dimensions

97x97x58 mm (3,8x3,8x2,3 in)

ND1060 MEASURED WITH 1W INPUT ON RATED IMPEDANCE AT 1M DISTANCE ON XT1086 HORN MOUTH AXIS

FREE AIR IMPEDANCE MAGNITUDE CURVE

HF Neodymium Driver 8 Ohm

· 108 dB SPL 1W / 1m average sensitivity

· 1 inch exit throat

· 44 mm (1 3/4 inch) edgewound

· aluminum voice coil

· 80 Watt program power handling

· Treated polyethylene diaphragm

· Proprietary phase plug design

· Neodymium magnetic structure

· Excellent thermal exchange

The ND1060 1 inch exit neodymium high frequency compression driver has been designed for use in high quality audio system designs.

One advancement in the ND1060 is its new innovative diaphragm assembly made from a proprietary treated Polyethylene material. Consequently, the ND1060, with its inherent superior diaphragm dimensional stability (160°C), is able to maintain constant behavior during its whole working life. Moreover, the proprietary treated polyethylene film, with its very high value of modulus of elasticity (50% more than standard Mylar and 100% more than polyimide film), is capable of superior transient and intermodulation distortion response. The flat suspension shape has been designed to maintain low stiffness and low mid band distortion and response. An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Nomex shows a 30% higher value of tensile elongation at a working operative temperature (200°C) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Further, this proprietary former material is also suitable for use in high moisture content environments.

Equipped with unique proprietary phase plug architecture, the ND1060 has been designed to give high level manufacturing consistency and a smooth coherent wavefront at the horn entrance across the whole working frequency range. With its short openings and high flare rate value, this phase plug design assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction.

By careful use of elementary pieces of neodymium magnets, Eighteen Sound engineers have developed a powerful neodymium magnet assembly capable of reaching 18KGauss in the gap, within a compact and lightweight structure.

A copper ring on the pole piece reduces inductance above 10 kHz, improving phase and impedance linearization. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading.

Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover which facilitates a lower power compression value.

The ability to perform properly under inclement weather conditions is a key-point in the Eighteen Sound philosophy. A special treatment has been applied to the magnet and the top and back plates of the magnetic structure making the ND1060 driver more resistant to the corrosive effects of salts and oxidization. This treatment is more effective than any other treatment used by other manufacturers.

One advancement in the ND1060 is its new innovative diaphragm assembly made from a proprietary treated Polyethylene material. Consequently, the ND1060, with its inherent superior diaphragm dimensional stability (160°C), is able to maintain constant behavior during its whole working life. Moreover, the proprietary treated polyethylene film, with its very high value of modulus of elasticity (50% more than standard Mylar and 100% more than polyimide film), is capable of superior transient and intermodulation distortion response. The flat suspension shape has been designed to maintain low stiffness and low mid band distortion and response. An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Nomex shows a 30% higher value of tensile elongation at a working operative temperature (200°C) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Further, this proprietary former material is also suitable for use in high moisture content environments.

Equipped with unique proprietary phase plug architecture, the ND1060 has been designed to give high level manufacturing consistency and a smooth coherent wavefront at the horn entrance across the whole working frequency range. With its short openings and high flare rate value, this phase plug design assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction.

By careful use of elementary pieces of neodymium magnets, Eighteen Sound engineers have developed a powerful neodymium magnet assembly capable of reaching 18KGauss in the gap, within a compact and lightweight structure.

A copper ring on the pole piece reduces inductance above 10 kHz, improving phase and impedance linearization. The custom designed O-ring creates a tight seal between the plate and the cover assuring air chamber loading.

Excellent heat dissipation and thermal exchange are guaranteed by the direct contact between the magnetic structure and the aluminum cover which facilitates a lower power compression value.

The ability to perform properly under inclement weather conditions is a key-point in the Eighteen Sound philosophy. A special treatment has been applied to the magnet and the top and back plates of the magnetic structure making the ND1060 driver more resistant to the corrosive effects of salts and oxidization. This treatment is more effective than any other treatment used by other manufacturers.

| GENERAL SPECIFICATIONS | |

| Throat Diameter | 25,4 mm (1 in) |

| Rated Impedance | 8 ohm |

| DC Resistance | 5,3 Ohm |

| Minimum Impedance | 7 Ohm at 4000Hz |

| Le (at 1kHz) | 67 µH |

| AES power | 40 W above 1,6 kHz |

| Program power | 80 W above 1,6 kHz |

| Sensitivity(1W@1m) | 108 dB |

| Frequency Range | 1600Hz ÷ 20kHz |

| Recomm. Xover Frequency | 1600Hz (12dB/oct slope) |

| Diaphragm Material | Treated polyethylene |

| Voice Coil Diameter | 44,4mm (1 3/4 in) |

| Voice Coil Winding Material | Edge-wound aluminum |

| Magnet Material | Neodymium |

| Flux Density | 1,8 T |

| BL Factor | 8,7 N/A |

| Polarity | Positive voltage on + terminal gives positive pressure in the throat |

| MOUNTING INFORMATIONS | |

| Overall diameter | 98 mm (3,9 in) |

| Mounting holes diameter | 4 M6 holes 90° at Ø 76 mm (3 in) |

| Bolt circle diameter | 76 mm (3 in) |

| Total depth | 53 mm (2,1 in) |

| Net weight | 1,1 Kg (2,4 lb) |

| Shipping weight | 1,2 Kg (2,6 lb) |

| CardBoard Packaging dimensions | 97x97x58 mm (3,8x3,8x2,3 in) |

ND1060 MEASURED WITH 1W INPUT ON RATED IMPEDANCE AT 1M DISTANCE ON XT1086 HORN MOUTH AXIS

FREE AIR IMPEDANCE MAGNITUDE CURVE

Ocena: