EIGHTEEN SOUND HD1040

Šifra: 4882

Na stanju

90,00 EUR

*Cijena sa popustom može se ostvariti ukoliko se plaća gotovinom, virmanom (preko računa) ili debitnom i kreditnom karticom odmah i odjednom.

Prikazana cijena je za komad.

Garantiramo najnižu cijenu na tržištu!

U slučaju da pronađete isti proizvod po povoljnijoj cijeni,

molimo Vas da nas kontaktirate na:

info@player.hr

HF Compression Driver 8 Ohm

· 1 inch exit throat

· 107 dB SPL 1W / 1m average sensitivity

· 44mm (1 3/4 inch) voice coil diameter

· 80 Watt program power handling

· Treated polyethylene diaphragm

· Proprietary phase plug design

HF Compression Driver 8 Ohm

· 1 inch exit throat

· 107 dB SPL 1W / 1m average sensitivity

· 44mm (1 3/4 inch) voice coil diameter

· 80 Watt program power handling

· Treated polyethylene diaphragm

· Proprietary phase plug design

The HD1040 one inch exit high frequency compression driver has been designed for use in high quality audio systems.

Equipped with proprietary Phase Plug architecture, the HD1040 has been designed to give high level manufacturing consistency and smooth coherent wave front at the horn entrance across the whole working frequency range. The phase plug with its short openings and high flare rate value assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction.

The HD1040 diaphragm assembly is made by proprietary treated Polyethylene material. Thanks to its superior diaphragm dimensional stability (160°C), the polyethilene shows constant behaviour during its whole working life. Moreover, this particular material with its very high value of elasticity modulus, (50% more than standard Mylar and 100% more than polyimide film) is capable of superior transient and intermodulation distortion response. The flat suspension shape is designed to maintain low stiffness and low mid band distortion and response.

An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Thanks to its physical properties, the proprietary treated Nomex former shows a 30% higher value of tensile elongation at a working operative temperature, (200°C) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Moreover, this proprietary former material is suitable for use in damp and wet environments.

The HD1040 powerful ceramic magnet assembly has been designed to obtain 16 KGauss in the gap within a compact ferrite motor structure.

Equipped with proprietary Phase Plug architecture, the HD1040 has been designed to give high level manufacturing consistency and smooth coherent wave front at the horn entrance across the whole working frequency range. The phase plug with its short openings and high flare rate value assures low distortion and demonstrates remarkable improvements in mid-high frequency reproduction.

The HD1040 diaphragm assembly is made by proprietary treated Polyethylene material. Thanks to its superior diaphragm dimensional stability (160°C), the polyethilene shows constant behaviour during its whole working life. Moreover, this particular material with its very high value of elasticity modulus, (50% more than standard Mylar and 100% more than polyimide film) is capable of superior transient and intermodulation distortion response. The flat suspension shape is designed to maintain low stiffness and low mid band distortion and response.

An edge-wound aluminum voice coil wound on proprietary treated Nomex completes the diaphragm assembly. Thanks to its physical properties, the proprietary treated Nomex former shows a 30% higher value of tensile elongation at a working operative temperature, (200°C) when compared to Kapton. This feature enables proper energy transfer control from the voice coil to the dome in real working conditions. Moreover, this proprietary former material is suitable for use in damp and wet environments.

The HD1040 powerful ceramic magnet assembly has been designed to obtain 16 KGauss in the gap within a compact ferrite motor structure.

| GENERAL SPECIFICATIONS | |

| Throat Diameter | 25,4 mm (1 in) |

| Rated Impedance | 8 ohm |

| DC Resistance | 5,3 Ohm |

| Minimum Impedance | 7 Ohm at 4000Hz |

| AES power | 40 W above 1,6 kHz |

| Program power | 80 W above 1,6 kHz |

| Sensitivity(1W@1m) | 107 dB |

| Frequency Range | 1600Hz ÷ 20kHz |

| Recomm. Xover Frequency | 1600Hz (12dB/oct slope) |

| Diaphragm Material | Treated polyethylene |

| Voice Coil Diameter | 44,4mm (1 3/4 in) |

| Voice Coil Winding Material | Edge-wound aluminum |

| Magnet Material | Ferrite |

| Flux Density | 1,6 T |

| BL Factor | 7,4 N/A |

| Polarity | Positive voltage on + terminal gives positive pressure in the throat |

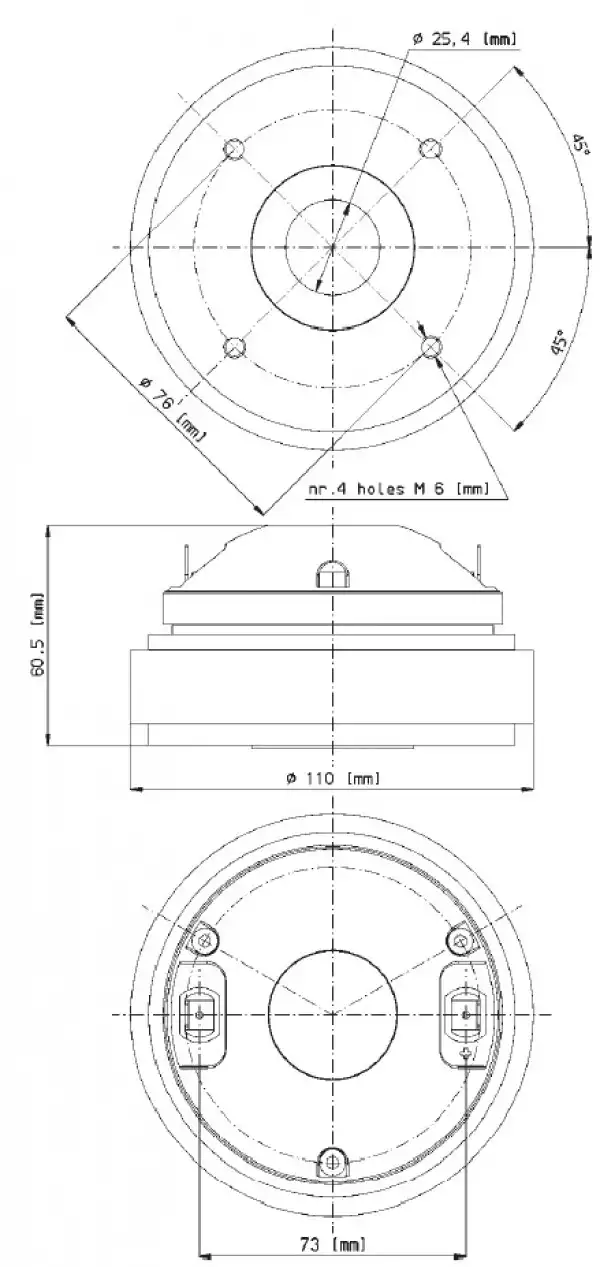

| MOUNTING INFORMATIONS | |

| Overall diameter | 110 mm (4,3 in) |

| Mounting holes diameter | 4 M6 holes 90° at Ø 76 mm (3 in) |

| Bolt circle diameter | 76 mm (3 in) |

| Total depth | 60,5 mm (2,38 in) |

| Net weight | 1,8 Kg (4 lb) |

| Shipping weight | 1,9 Kg (4,22 lb) |

| CardBoard Packaging dimensions | 110x110x63 mm (4,3x4,3x2,5 in) |

Ocena: